(603) 716-4025

(603) 716-4025

AIrAnalytics™ quickly identifies and saves your business money in near real time using monitoring-based commissioning. The AIrAnalytics™ web-enabled dashboard provides actionable insight and sustainability—powered by CES’s 10+ years being a technical service provider to one of the largest utility companies in the country—like no other system on the market.

With the launch of AIrAnalytics™, Compressor Energy Services continues our commitment to take compressed air systems energy and operational efficiency to a new standard. The system promises to blow away comparable providers’ offerings.

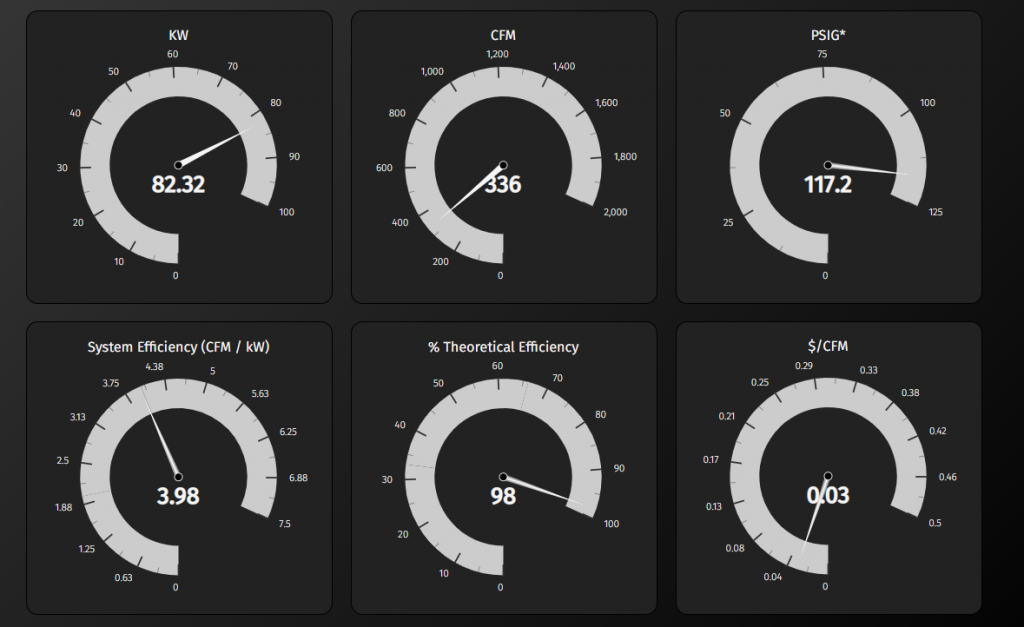

Monitor the efficiency of your compressed air system with real-time system-level data capturing key KPIs, kW, Cost, CFM, PSI, and CFM/kW. Get emails or text message alerts for set-points and active factors that could cause shutdown or inefficiencies. Drill down into the near-live status of each compressor.

One statistic that keeps coming up from all the major companies that are working on initiatives in this space is that less than 1 percent of the data that they are collecting is actually being used. CES has changed that narrative!

Request a Demo

Contact CES to find out how we work with utilities to maximize energy savings.

How AIrAnalytics™ Helps Our Customers

CES guarantees energy savings that result in a typical return on investment of 65%, resulting in simple paybacks of months, not years.

- Trending analytics with in-house expertise analysis eliminates drift while maximizing compressed air efficiencies.

- AirAnalytics™ integrates with any MES or ERP system.

- Real-time, 24/7 Investment-Grade analysis that measures power-flow-pressure that equate to bottom-line kWh/$ savings

- Near real-time operational tracking (current)

- Automatic reporting that is easily customized

- Supply & Demand system optimization

- All data, streaming and historical, is available for detailed review

- 100% scalable from a small single system to large enterprise customers

- Clean, intuitive visualization

How AIrAnalytics™ Helps Utility Companies

- Trending analytics with in-house analysis expertise eliminates drift while maximizing compressed air efficiencies (persistent of savings)

- 100% realization and data for evaluators

- MBCx

- Heatmap and continuous comparison of data

- Pre- and post- Measurement & Verification. M&V is continuously compared to trending, heatmaps, and other pertinent KPIs.

- Downloadable raw data

- Real-time, 24/7 Investment-Grade that measures power-flow-pressure that equate to bottom-line kWh/$ savings

- We partner with utilities to secure kWh and improve the realization rate.

- Utility reporting that is easily customized to meet the needs of all utility stakeholders.

- All data, streaming and historical is available for detailed review (in near real-time).

- 100% scalable from a small single system to large enterprise customers

- Clean, intuitive visualization

- Library of pre- and post-data, provides true base cases.

- Largest database of Compressor Air Systems with 5 second data in the country

- Comparative Analysis—region, states, utilities, customers, system types, control methods & storage

Key Product Features

- Cost tracking on a near real-time basis for the week.

- Adjustable alerts to ensure the system is operating as designed.

- Ability to review kW by calendar by the hour, down to 5 seconds, as well as a maximum CFM, PSI, or kW.

- Users can export reports as images or download them as PDFs. The hardware tracked report, for instance, shows the cost per compressor to operate and how much power is being used.

- Sign up for daily, weekly, or monthly emails or texts with summary reports of system kWh totals, compressor totals, etc. Also get notifications to track particular thresholds, events, and performance triggers.

- Permission-level access control

- OTA software updates

We have been fortunate to work with some very talented consultants like Jeff Wright from Compressor Energy Services. He is a systems engineer who shares my goal to shut off air compressors and save power. We rarely talk about air compressor technologies—just about demand-side efficiency opportunities. We talk about measurement techniques and about how to interpret and understand data.